The procedure begins with the identification of a need, followed by a choice. The procedure culminates in the presentation of a project that satisfies the request after extensive iteration.

Solid modeling, assembly modeling and drafting, finite element analysis, direct and parametric modeling, and finite element analysis are all available.

It is more user-friendly than any other solid modeling CAD software.

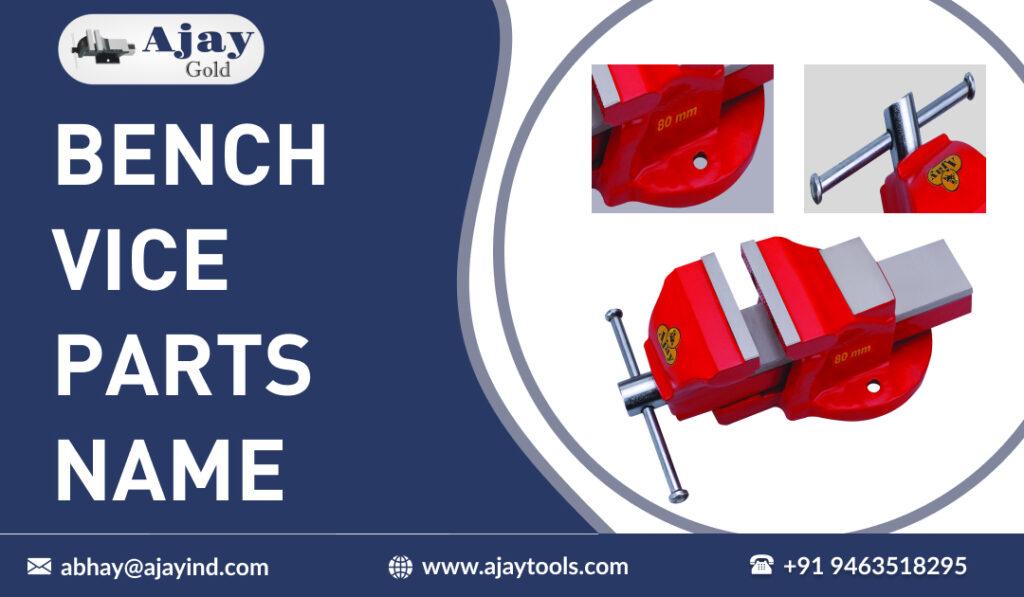

Bench Vice Parts

- Fixed Jaw

- Jaw Plate

- Handle Rod

- Handle Nut

- Flat Tapping Screw

- Vise Screw

- Design of Each Part of Bench Vise

Solid modeling, assembly modeling and drafting, finite element analysis, direct and parametric modeling, and finite element analysis are all available. It is more user-friendly than any other solid modeling CAD software.

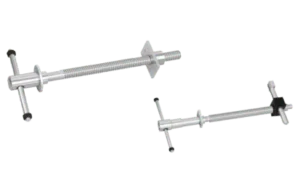

Design of Vise Screw

The function of the vise screw on a bench vise is to provide to and fro movement for the moveable jaw. In both fixed and moveable jaws, this is utilized to tighten the workpiece.

Design of Collar

A collar is a circular ring that goes around a vise screw to strengthen it, particularly where the screw head and moveable jaw are to be linked for movable jaw movement. It is situated between the screw head and the movable jaw’s base. When tightening the workpiece between the jaws, also provides firm support for the screw head.

Design of Jaw Plate

It is attached to both the fixed and moveable jaws. Its purpose is to keep a strong grip on the work item while performing various operations on it. On the gripping surface, diamond knurling is given for effective grip. Different jaw plates can be utilized depending on the material of the workpiece and the requirements.

Design of Sliding Jaw

The moveable jaw, often known as the sliding jaw, is used to hold the workpiece between the fixed and movable jaws. To hold the workpiece, the sliding jaw can be moved to and fro depending upon the size of the workpiece. It is usually made of Cast Iron (CI). It is a stiff element of the bench vise that allows it to remain steady throughout operations.

Design of Vise Handle

When tightening and loosening a workpiece between two jaws is required, the function of the vise handle is to rotate the vise screw. It is put into the vise screw’s supplied hole. The vise handle has a threaded component on one side and a ball-headed side is on another side.

Design of Handle Nut

This nut is attached to the vise’s handle. Its purpose is to keep the vice handle from sliding off the vise screw.

Design of Flat Tapping Screw

The tapping screw is used to secure the jaw plate to both the sliding and fixed jaws, which are utilized to retain the workpiece. With the aid of an Allen key, it is tightened. For each jaw, two tapping screws are usually required.

Design of Fixed Jaw of Bench Vise

The bench vise’s fixed jaw is the essential component that supports the entire assembly. With the help of nut and bolt arrangements on both sides, the fixed jaw is rigidly fixed on the workbench. Its purpose is to guide the to-and-fro movement of the movable jaw and the vise screw.

The work item is kept between the fixed and moveable jaws, and heat stresses and significant forces are applied to it while it is being worked on. As a result, the moveable jaw should be thermally robust and capable of withstanding considerable stresses.

Design of Modified Fixed Jaw

The traditional fixed jaw is modified in this modification so that it can take the shape of a surface plate. This change will make it easier to determine if two faces are at a 90-degree angle or not. This update will save time when measuring the 90-degree angle between any two sides on a regular basis. Because some of the material from the fixed jaw is removed during this adjustment, it is much less expensive. This tool cannot be used to measure jobs with dimensions greater than 90*92 mm.

Final Say

We hope that you acquire all the information related to different bench vice parts names. Ajay Tools is one of the best manufacturers in India, who manufactures and delivers quality bench vices all over the world.