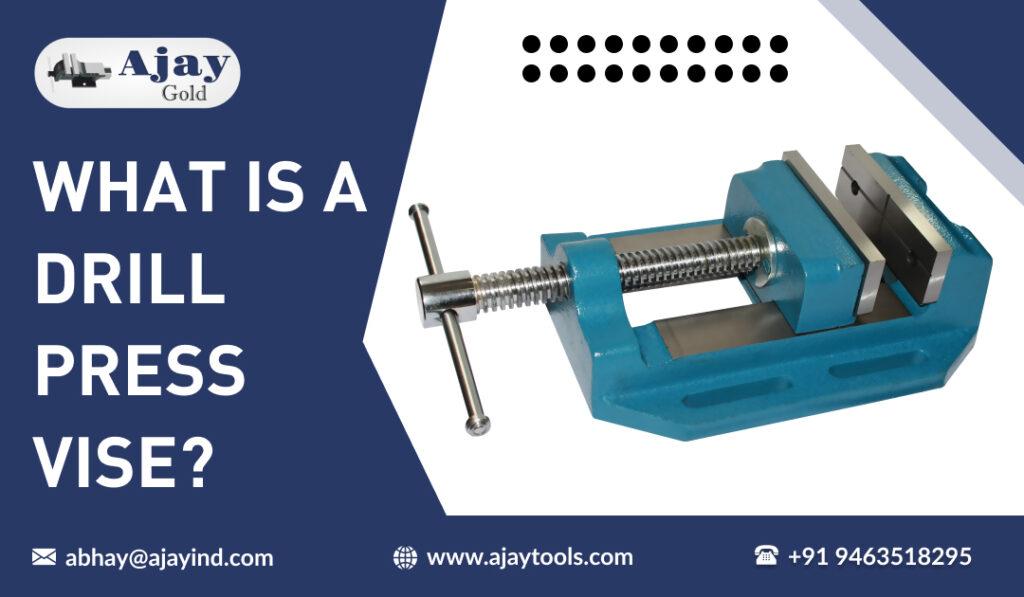

A drill press vise is a tool that holds a workpiece in place between its jaws so that it does not move when the drill bit is driven into it. It uses a threaded rod to force two jaws together, similar to other vises. Some drill press vises are clamped to the table, while others are secured to the table via the miter-gauge hole.

The fact that most drill press vises have jaw openings of only 6 or 7 inches (15.24 – 17.78 cm) is a significant disadvantage; larger workpieces must be fastened in other ways.

A drill vice is a stationary power drill that drills holes with a significantly higher degree of accuracy than a manual drill in most machine shops and wood industries. It is commonly built into a strong cast-iron frame that stands on the floor or on a workbench to boost its stability.

The workpiece is put on the work surface, and the operator presses the rotating drill bit into the workpiece by turning a handle. The drill bit drills a hole in the workpiece at the depth set by the operator.

There are two methods for firmly securing a workpiece to prevent most movement. The first method is to secure the workpiece to the table with clamps, and the second method is to utilize a drill press vise.

Drill machine vice clamps are ideal for large or irregularly shaped workpieces, but not for thicker or taller parts, such as when drilling out the core of a lamp base. Drill press vises, as well as narrower workpieces that fit between the jaws of the vise, are ideal for these goods.

A drill vise is ideal for some types of production work that require several holes to be drilled. The vise is set in place and tightened once the first hole’s placement is chosen, and the hole is drilled. The workpiece is shifted and the vise is untied so that the next hole location is aligned with the drill bit.

All that’s left to do now is make sure the drill bit is properly aligned and the vise is tightened again. When drilling holes in many identical workpieces, the same logic applies; after the drill press vise is fastened to the work table, the work can move faster since the vise’s immovable jaw functions as a fence.

How to Use a Quick-Release Drill Press Vise?

Operating a quick-release drill press is easy and similar to using a standard drill press. The key benefit is that its design makes one-handed operation considerably easier and it is much easier to move than a traditional drill press vise.

To utilize a quick-release drill press jaw, you must first open it, position the workpiece, and then close it. This is a rather straightforward section.

The drill vice’s mounting holes must then be aligned with the table’s drilling holes. A bolt holds the quick-release clasp in place. Thread the bolt through the hole after placing a washer on either side of the drilled hole. The table’s quick-release clasp should be on the underside.

- Although a drill press vise is not designed for milling, lightly milling an 80% lower can be done safely.

- Only minimal “drill” milling and polishing of the walls and floor are required to complete the receiver.

- When milling with your drill, maintain a low feed rate (SFM) of 1 foot per minute.

- To keep the drill bit from falling out always use conventional or up milling.

- To keep the receiver and bit cool while cutting, use a lot of machining oil and lubricant.

Ajay Tools is the leading company in manufacturing and delivering drill press vice heavy duty. The frame is made up of graded cast iron with a forged spindle. Jaws are made up of En-8 steel and case hardened for extra strength. Horizontal degree for gripping of round objects.

Final Say

Ajay Tools Company is well-known among the hand tools manufacturers in India. They provide excellent hand tools to individuals for better crating and other activities. They are delivering their best drill machine vice all over the world.